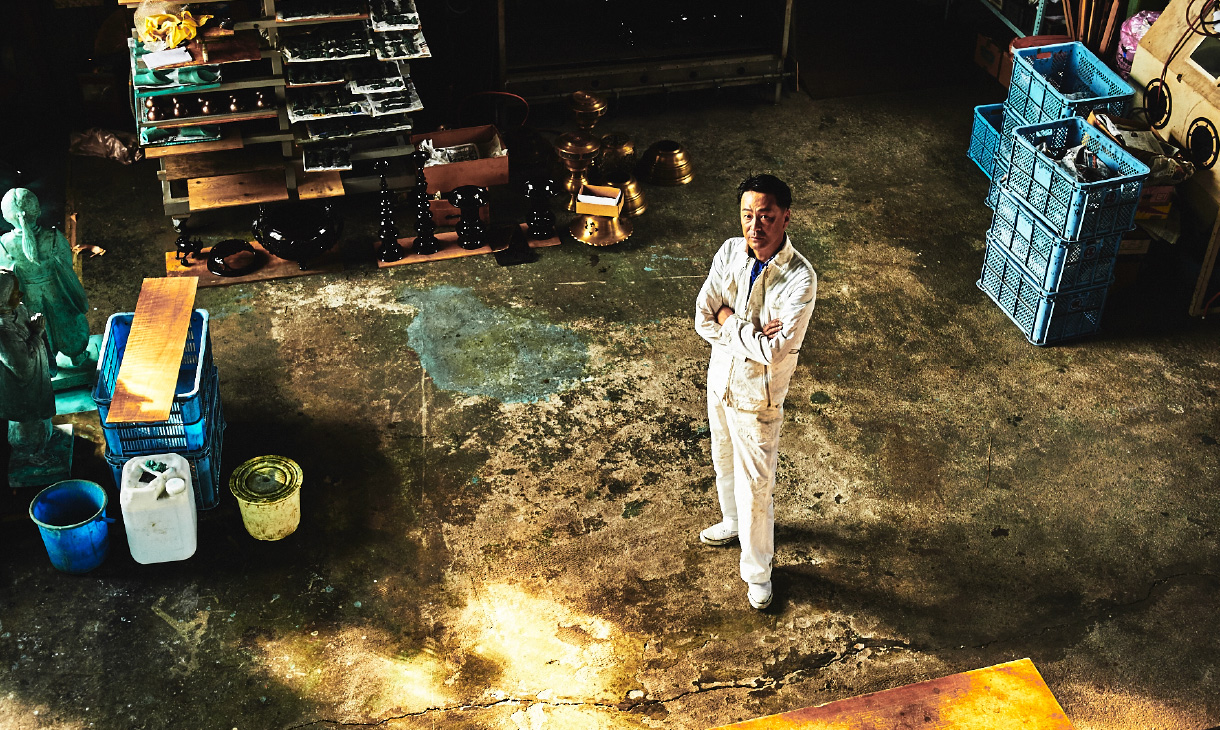

唯一無二の発色と質感

Oriiの生み出す無限の色。

魔法のように浮かぶ模様。

一枚の金属に、職人の手とイマジネーションで、千変万化の表情を描く独自の技法は、どこにもない、Oriiオリジナルの発色をもたらします。

Orii creates unlimited color.

The designs materialize like magic.

Matal plate in the hands of skilled artisans undergo unending metamorphosis inexplicably transformed into an Orii original.

Instagram@orii_showroom

Instagram@orii_showroom

Online Shop

Online Shop

WHAT’S NEW

| 2024.04.10 | 2024年日米首脳会談のバイデン大統領夫人への贈答品に当社の着色を使用したアクセサリーが選ばれました |

| 2024.03.14 | 【ひなフェスin山町ヴァレー&サカサカ】@Orii gallery 八ノ蔵 |

| 2024.03.14 | JAPAN SHOP 2024【2024.3.12〜3.15】 |

| 2024.03.01 | 新商品のご案内 |

| 2024.02.26 | 【イベント】2024.3.6~3.12 大丸京都店 |

| 2024.02.26 | 2024.3 第5回京都インターナショナル・ギフト・ショー2024に出展します |

| 2024.02.26 | 【POPUP開催中】@京都岡崎 蔦屋書店 |

| 2024.01.11 | 【POPUP開催中】@WELLSPRING石川店 |

| 2024.01.10 | 2024年/営業日変更のお知らせ |

| 2023.12.14 | 2023年/年末年始 休業のお知らせ |